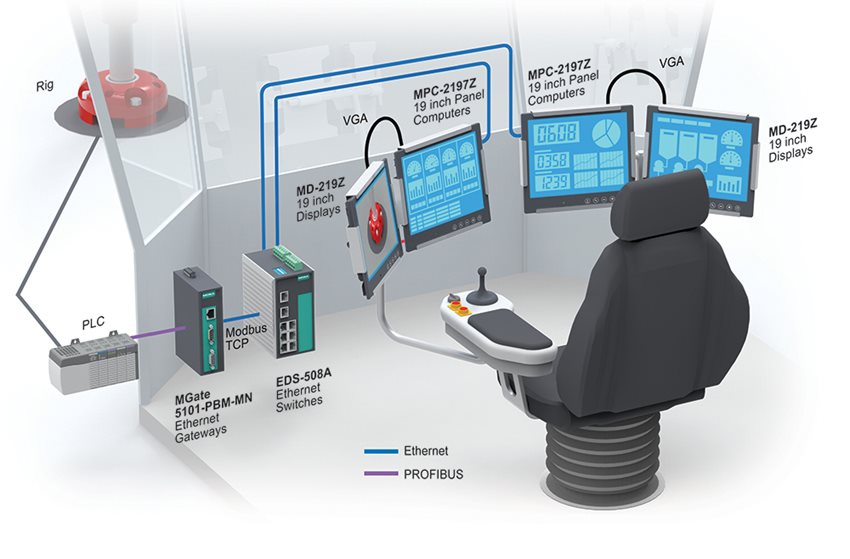

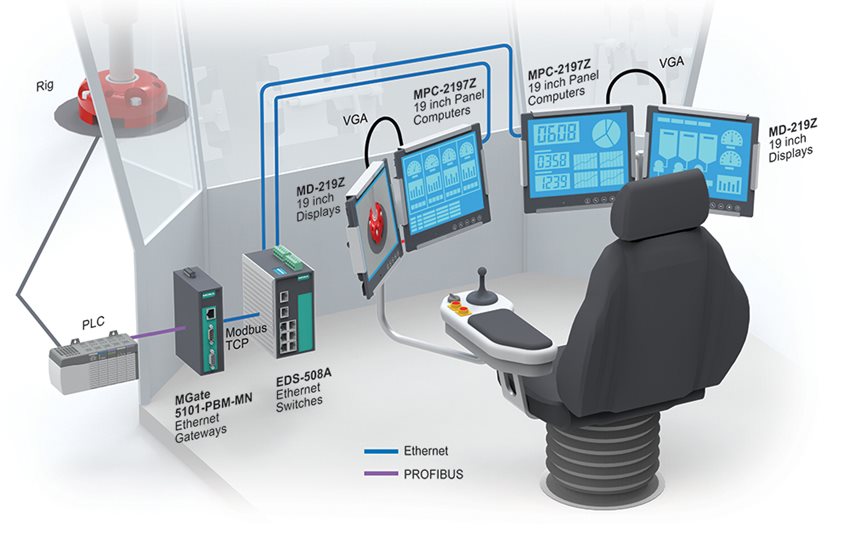

In the previous system, four displays were connected to the drilling chair to show drilling parameters. About 100 meters away, PCs in the control room were connected to displays around the drilling chair using VGA cables. There was frequent interference in signal transmission. The system was unable to support client's progression towards digital oilfields.

The client wanted to upgrade the drilling control system to be compatible with next generation devices and digital oilfields.

System Requirements

1. Panel computers that can replace existing PCs and displays

2. High processor performance and more touch responsive panel computers

3. PROFINET-to-Ethernet gateways to connect PLCs and computers for seamless data transmission and easy integration

4. Class 1 Division 2 ATEX and IECEx certifications, as well as wide operating temperature range

Solution

The implementation was cost effective and improved operational efficiency and transformed the existing system towards digital oilfields. Two existing PCs and two displays were replaced with Moxa’s MPC-2197Z touch panel computers and Moxa’s MD-219Z displays. To improve efficiency, Moxa panel computers were installed to the drilling chair. The long VGA cable connection was discontinued. The new layout make it easier for operator to perform drilling.

The metallic frame of the previous displays made it difficult for operator to touch the screen around the metallic frame where the ‘close’ button is located. Moxa’s MPC-2197Z flat panel computers features sensitive multi-touch capabilities that avoid any interoperability issues and enhance operational efficiency.

To progress towards digital oilfields, the new system needed to support protocol conversion. PROFIBUS is the most common PLC protocol at oil & gas field sites, . Moxa’s MGate 5101 Ethernet gateway was used to enable direct connectivity to the panel computer. The upgraded system incorporated Moxa's EDS-508A managed ethernet switches and Moxa's MXView to allow network visibility.

This product is export-ready and classified under an international HS Code for smooth customs clearance. TNS ships worldwide via DHL Express, providing fast and reliable international delivery.

For customers in Singapore, we offer free local shipping on orders above SGD $80 — no extra handling fees.

Please contact TNS for key shipping and compliance details to support both local and international logistics planning.