Overview

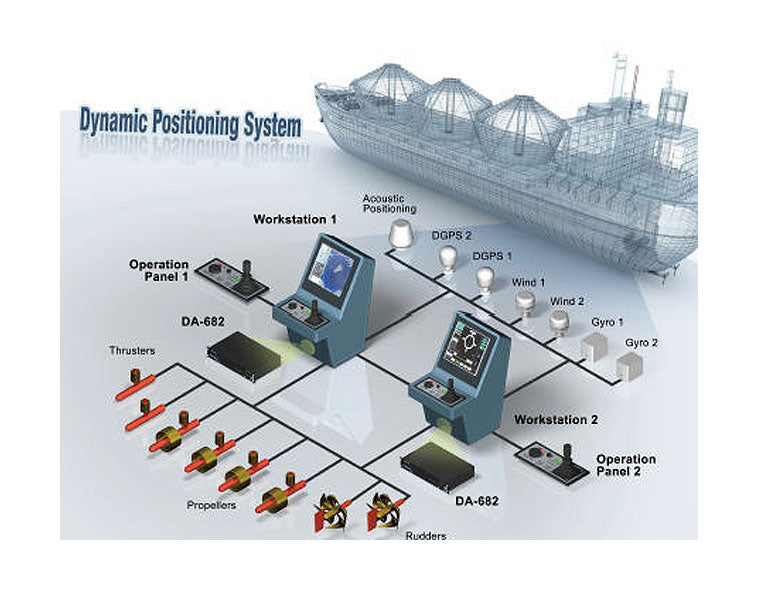

Dynamic Positioning Systems (DPS) are critical tools for maintaining the position of deep well drilling rigs on the open sea, or for piloting ships and barges to dock through crowded harbours.

Originally developed in the 1960’s for drilling rigs, today dynamic positioning systems are used in a wide variety of other important maritime applications that have nothing to do with oil production: cable layers, ocean surveyors, salvage vessels, dredging ships, floating hotels, cruise ships, the Sea Launch service, and many other types of industrial and commercial vessels all require dynamic positioning to go about their daily work. Dynamic positioning systems (DPS) have thus become one of the maritime industries’ most critical navigational aids, requiring durable and reliable industrial-grade components that may be easily integrated with existing ship technology.

One of the core requirements for a DPS computer is the capacity for easily and securely integrating a variety of already existing ship systems. The computer that will serve as the main processing hub in a DPS must be capable of conveniently linking to subsystems like gyro compasses, motion sensors, and wind sensors. For all but the most rudimentary dynamic positioning systems, this requires a computer that is capable of managing computationally-intensive automated control systems that calculate in real-time every possible effect on the ship’s position: pitch, sway, heave, yaw, roll, and surge. Thus, effective computing units for DPS are industrial-grade, high performance embedded platforms that built with processors that are powerful and reliable enough to stably crunch a lot of data in real time, even under the harsh environmental conditions found on ships at sea.

System Requirements

• Large number of native serial interfaces

• Extremely Durable reliability

• High computing performance

• Quick, effective after-sale service

Solution

One of the world’s leading manufacturers of dynamic positioning systems chose the Moxa DA-682 embedded computer to be the heart of its DPS. A standard DPS workstation is served by a trio of DA-682 computers housed in two separate workstations, to protect against loss of DPS control on the open seas by providing full system redundancy at every level.

While the DA-682s fulfilled the specified durability and performance requirements, what really made the DA-682 stand out from other systems were its sixteen software-selectable serial interfaces. These sixteen serial ports come in two removable modules of eight each, and may be configured for use as RS-232, -422, or -485 interfaces.

Delivery | Can I select a specific time for delivery?

Delivery | Can I select a specific time for delivery?

We are unable to allocate a specific time for delivery. You may let us know your preferred timing and we will try our best to meet your request if possible.

Delivery | Do you have self collection option for urgent request?

Delivery | Do you have self collection option for urgent request?

Yes, for urgent purchases, please contact TNS before placing your order

Delivery | Do you provide International Shipping?

Delivery | Do you provide International Shipping?

Yes, TNS offers international shipping out of Singapore. Our delivery partners are Fedex and DHL. Product prices quoted on our website is in Singapore currency by default.

Delivery | Is there free delivery service?

Delivery | Is there free delivery service?

Enjoy free local delivery service for online order over S$80. Free delivery service is within Singapore mainland (excluding Jurong Island, shipyards and restricted locations).

Purchase | Can I use my nickname or alias when placing my order?

Purchase | Can I use my nickname or alias when placing my order?

To ensure the safe delivery of your order, it is recommended to indicate your full name that matches your valid identification document (ID).

Purchase | What is the minimum order?

Purchase | What is the minimum order?

Unless specified, there is no minimum order.

Purchase | What payment methods do you accept?

Purchase | What payment methods do you accept?

TNS accepts payment via credit card, paynow transfer, cash and funds wired to our bank.

Support | Do I need to register for product warranty?

Support | Do I need to register for product warranty?

No registration is necessary. Your product is registered at the time of purchase.

Support | How do I configure/use/troubleshoot Moxa & Axiomtek products?

Support | How do I configure/use/troubleshoot Moxa & Axiomtek products?

TNS offers advice on product configuration and technical support. Our support hotline +65-67476740 is open from 9am to 5.30pm on weekdays. You can also email your questions to us.

This product is export-ready and classified under an international HS Code for smooth customs clearance. TNS ships worldwide via DHL Express, providing fast and reliable international delivery.

For customers in Singapore, we offer free local shipping on orders above SGD $80 — no extra handling fees.

Below are key shipping and compliance details to support both local and international logistics planning.